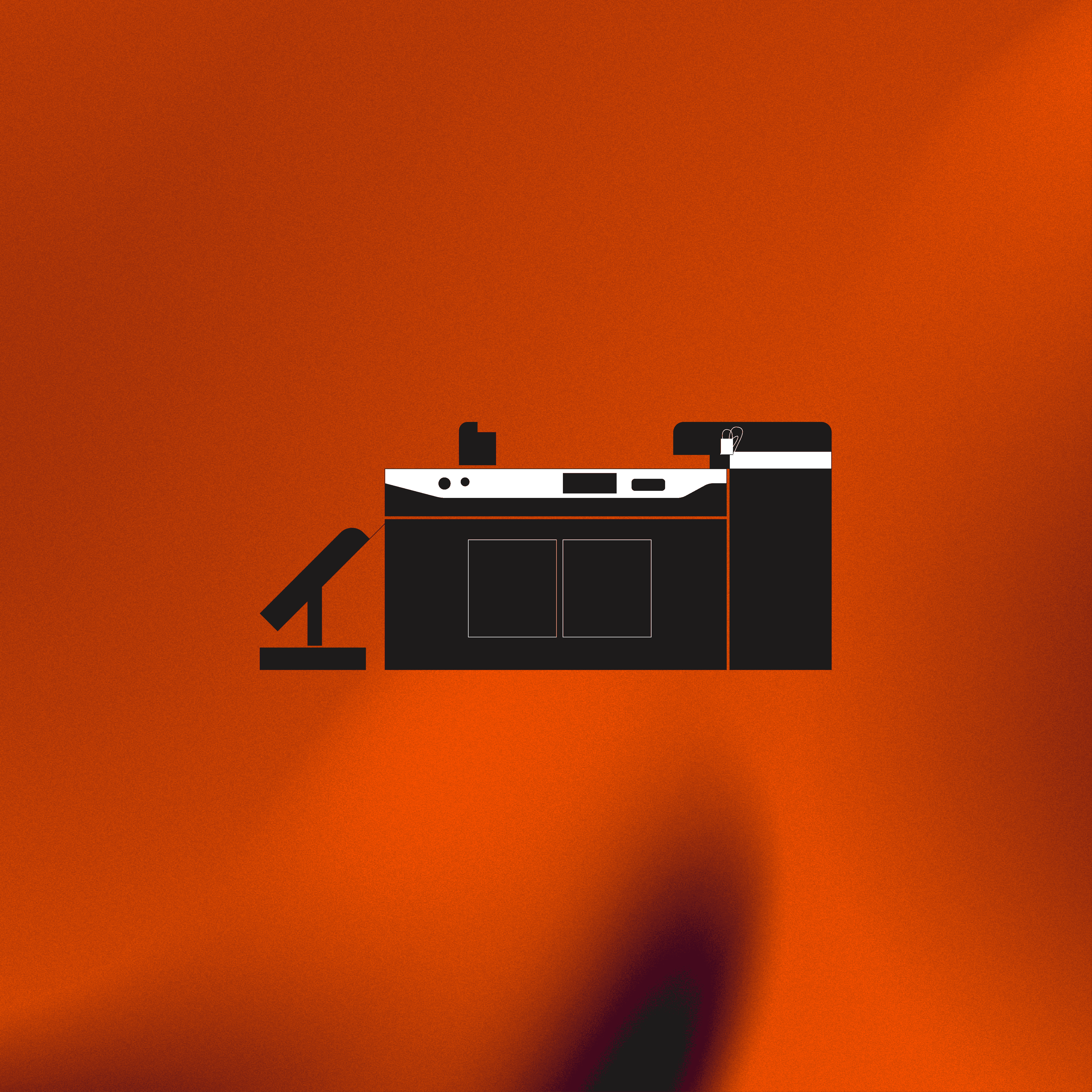

Morgana AeroCut X Pro

The Morgana AeroCut X Pro is a high-end multifunction finishing system designed to automate slitting, cutting, creasing and perforating in one streamlined process. It supports oversized stocks from digital or litho presses and is built for production environments where speed, accuracy and flexibility matter. With its intuitive touchscreen interface, powerful feeding mechanism and robust build, it significantly reduces finishing bottlenecks and elevates quality across business cards, postcards, tickets, invitations and other digitally printed items.

Key Specifications

Maximum sheet size: up to 370 × 750 mm (with optional extension up to ~1,600 mm)

Minimum finished size: 55 × 45 mm

Media weight range: 120–400 gsm (depending on stock quality)

Production speed: up to 68 sheets per minute (A4 single crease mode)

Dimensions (W × D × H): 1177 × 709 × 1076 mm; Weight: approximately 290 kg

Basic finishing functions included: slitting, cross-cutting, creasing, perforating, scoring, slit-score

Benefits

The AeroCut X Pro enables finishing operations to be carried out in a single pass—slitting, cutting, creasing and perforating—reducing manual interventions and improving throughput. Its large maximum sheet size and media weight range mean it handles oversized or heavy stocks that many finishing machines cannot. The intuitive 10″ touchscreen and automated feeding system lower operator training requirements and reduce risk of error. Its precision-engineered build delivers consistent, high-quality finishes even on complex jobs, making it a valuable asset for print suppliers aiming to raise their finishing capabilities and offer faster turnaround with minimal waste.

Designer / Production Tips

When preparing artwork for the AeroCut X Pro, ensure cut, crease and perforation lines are clearly defined—differentiated by stroke colour or layer—to ensure the machine’s dual modes are correctly applied. For heavy or textured stocks, specify thickness and weight so the correct settings and tools are engaged. The machine supports oversized lengths (up to ~1,600 mm) with optional extensions, so if your job requires long sheets notify pre-press early and plan bleed/margins accordingly. Although high speed is advertised, jobs with fine detail, multiple creases or perforations may benefit from slower modes to preserve precision. Also, when routing mixed-job stacks (for example, business cards plus postcards on the same setup), leverage the job memory feature (up to 266 presets) and the barcode reader capability for fast job change-over and minimal down-time.