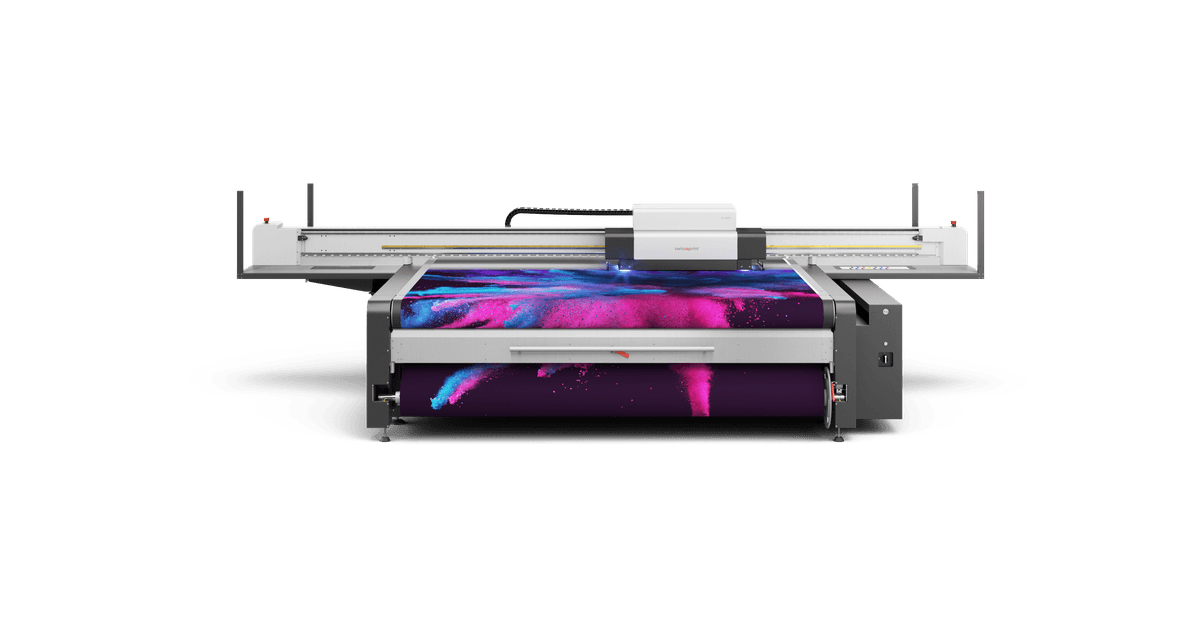

Swiss Q Nyala

The Nyala 5 is a high-performance large-format flatbed UV LED printer designed for fast, flexible and premium-quality production. It combines a 3.2 × 2 m print bed with a highly configurable colour system, making it suitable for signage, display, packaging, décor and fine-art applications. Its combination of speed, precision and media versatility positions it as a flagship option for print suppliers handling both high-volume work and specialist finishes.

Key Specifications

Print area: 3240 × 2030 mm

Maximum output speed: 253 m²/h

Colour channels: up to 10

Print heads: up to 20

Resolution: addressable up to 1350 dpi (visual up to 2540 dpi)

Maximum substrate thickness: approx. 50 mm

Substrate weight capacity: up to 30 kg/m²

Optional roll-to-roll width: up to 3.2 m

Oversize board option: up to 4 m printable length

LED UV curing for low-heat, energy-efficient operation

Benefits

The Nyala 5 delivers exceptional productivity, enabling quick turnaround times without compromising quality. Its combination of high speed and high resolution allows it to produce everything from everyday signage to premium photographic-grade work. The modular ink system supports additional channels such as white, varnish, orange and neon inks, making it ideal for creative applications, transparent materials and special-effect finishes. With its robust construction, strong vacuum hold-down and energy-efficient LED curing, the machine is designed for reliability, precision and long-term stability across a wide range of substrates.

Designer / Production Tips

Designers working with this machine can take advantage of its expanded ink set, especially when producing work on transparent or dark substrates where white or varnish layers are beneficial. Jobs requiring neon or orange inks should be clearly specified so the correct profiles are applied during pre-press. Although the Nyala 5 can achieve very high speeds, fine-detail or photographic work will run in slower quality modes, so planning for longer production times may be necessary. When preparing artwork for large rigid boards or oversized panels, ensure layouts respect the machine’s maximum sheet size and recommended bleed allowances. For roll media, accurate edge registration and appropriate tensioning are important, particularly when switching between roll and rigid workflows. Clear communication of substrate thickness, weight and finishing requirements will help ensure smooth production and optimal results.