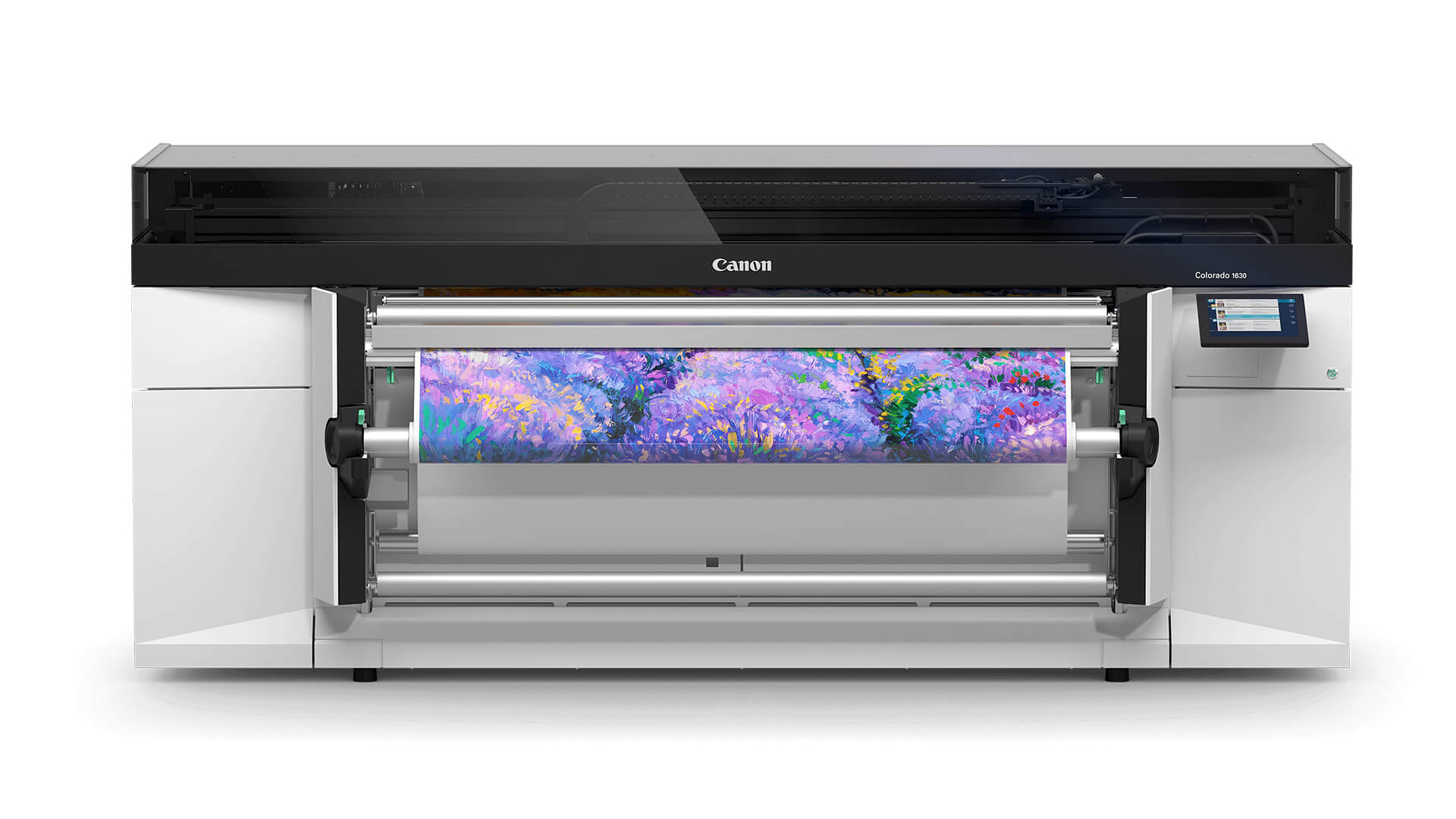

Canon Colorado

The Canon Colorado series is a high-performance large-format roll printer built on the UVgel ink platform. Designed for print suppliers seeking a combination of speed, flexibility and premium finish, it accommodates a wide variety of media including heat-sensitive materials, textured surfaces and large roll widths. With modular upgrade paths, optional white ink, and mixed gloss/matte finishing built-in, it’s well suited for high-volume signage, vehicle wraps, décor applications and more.

Key Specifications

Printing method: UVgel piezoelectric inkjet

Print resolution: Up to 1,800 dpi

Roll width: Up to 1,625 mm (64″)

Media thickness: Up to approx. 1.6 mm (varies by model)

Maximum roll weight: Up to 50 kg

Printing modes (example speeds for one model): Gloss up to ~159 m²/h; matte up to ~46 m²/h; mixed matte/gloss (via FLXfinish+) ~7 m²/h

Ink type: Canon UVgel 460 ink; colours: CMYK (with optional White)

Finish options: FLXfinish+ (matte/gloss or mixed in one pass)

Certifications & durability: Approved for e.g. 3M™ MCS Warranty when used with appropriate media.

Benefits

The Colorado series offers print-providers a strong combination of productivity and versatility. Its UVgel ink system enables fast drying and low-heat curing, making it safe for delicate or temperature-sensitive substrates. The option to print white and support mixed finishes in a single pass means creative applications — such as transparent media, vehicle graphics and high-end décor — are possible without separate processes. Its modular architecture allows initial investment at one level, with in-field upgrades for speed, white ink or dual-roll capability, making it future-proof. Also the reduced consumable usage, robust finish and high media range support a lower total cost of ownership and enable premium pricing for high-value jobs.

Designer / Production Tips

When designing for this printer series, consider clearly specifying the use of white ink or mixed gloss/matte finishes from the outset, so the correct modules and workflows are engaged. For delicate or heat-sensitive media, take advantage of the low-heat UVgel curing by specifying the substrate type. Although top-speed modes are impressive, higher quality or speciality modes will run slower — build realistic turnaround expectations accordingly. For dual-roll or long-run jobs, ensure correct substrate width, roll weight and diameter align with machine capabilities. Make sure artwork intended for mixed finishes uses proper layering or masks so matte/gloss transitions print correctly. Lastly, integrate finishing strategies (cutting, laminating, mounting) early in the brief since the high production rates demand efficient downstream workflows to avoid bottlenecks.