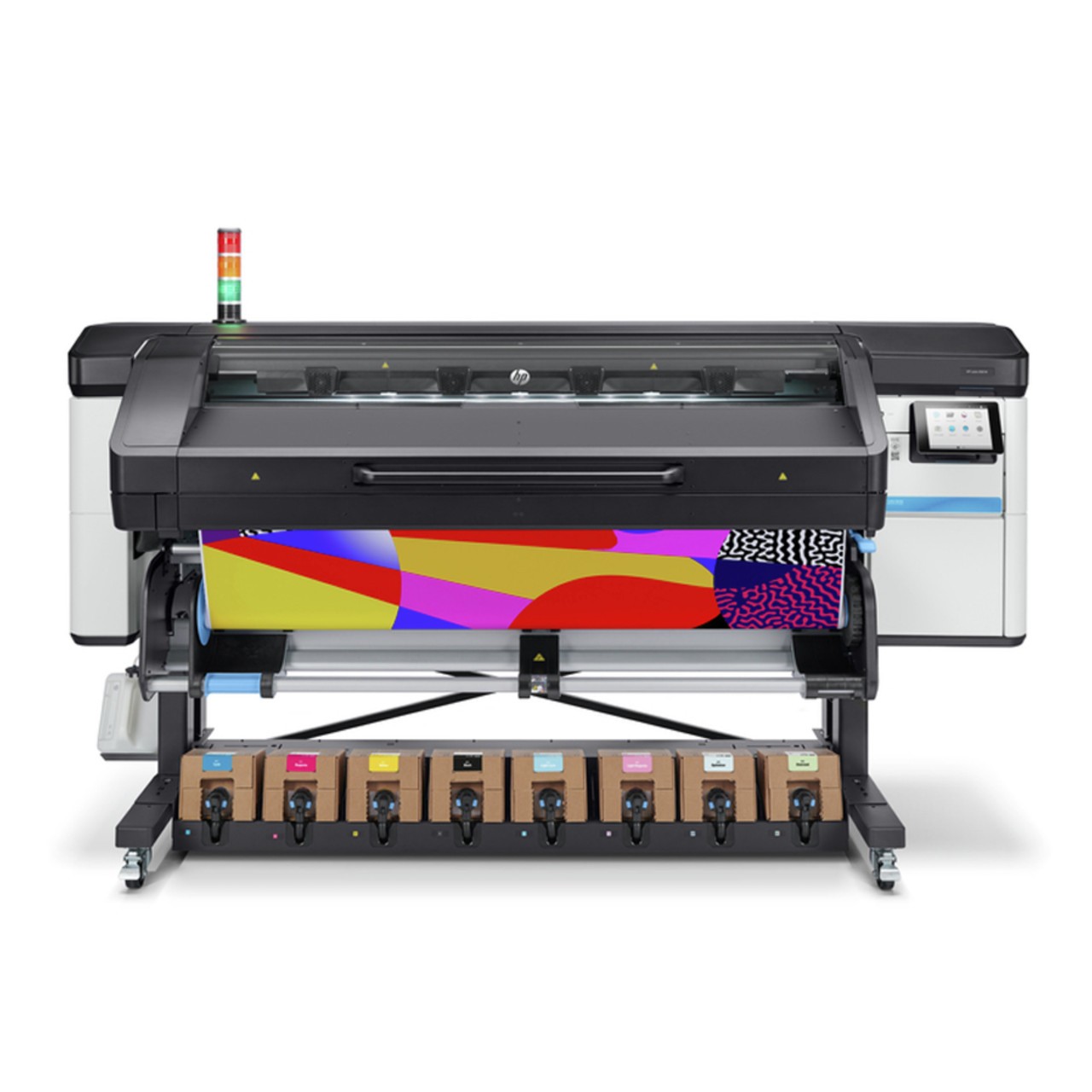

HP Latex

HP Latex printers are water-based large-format roll machines designed for high-quality signage, décor, display graphics and vehicle work with an extremely wide media range. The Latex ink system combines instant-drying, scratch-resistant output with low-heat curing and virtually no odour, making it ideal for indoor and outdoor applications. The printers are known for reliability, consistent colour and environmental friendliness, making them a staple choice for many print suppliers.

Key Specifications

Printing technology: Water-based HP Latex ink with thermal printheads

Print width (varies by model): typically 1371 mm to 1625 mm (54”–64”)

Resolution: up to 1200 × 1200 dpi

Ink colours: CMYK + LC + LM (with optional HP Latex Optimiser and HP Latex White in certain models)

Media compatibility: PVC, vinyl, banner, paper, textile, canvas, films, wallcoverings, heat-sensitive materials

Curing: Low-heat Latex curing for instant-ready prints

Typical top speeds: from fast draft modes (~20–30 m²/h) to high-quality modes (~6–12 m²/h), depending on model

Benefits

The HP Latex platform delivers highly durable prints that are instantly dry, scratch-resistant and odour-free, making it suitable for both retail interiors and demanding outdoor environments. Its water-based chemistry allows safe use in sensitive spaces without ventilation requirements. The broad media compatibility enables a single printer to handle banners, posters, vehicle wraps, canvas, textiles and wallpapers with consistent colour and smooth gradients. The thermal printheads are user-replaceable, reducing downtime and simplifying maintenance. White ink availability on newer models opens up opportunities for window graphics, coloured films and specialty coatings. Overall, the series is known for predictable colour, easy upkeep and stable production.

Designer / Production Tips

When preparing artwork for HP Latex printers, aim to avoid excessive ink density, as Latex tends to build colour vibrancy naturally — heavy saturations may impact curing speed. For vehicle graphics or stretch-sensitive materials, ensure correct ICC profiles and avoid oversaturated blacks to maintain flexibility. If using white ink on supported models, specify how the white should be applied (underprint, overprint or spot) so the RIP handles the layers correctly. Because prints come off the machine dry, finishing such as lamination or trimming can begin immediately, but for colour-critical work allow a short resting period to stabilise tones. For wallpaper and décor applications, maintain consistent panel overlaps and colour tolerances across long runs, as continuous tone consistency is one of the Latex platform’s strengths.