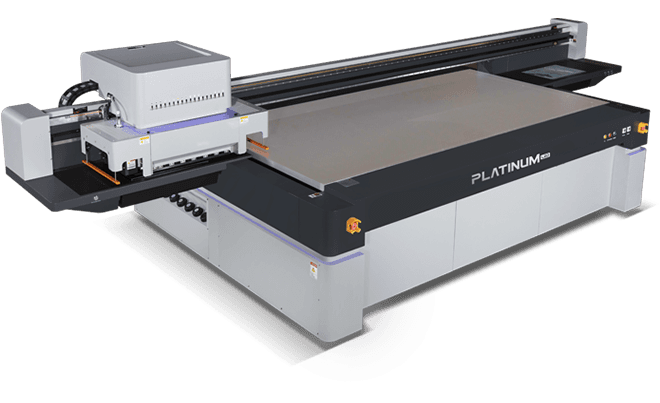

Liyu Platinum Q Cut 3521

The Platinum Q-Cut 3521 is a high-precision digital cutting table designed for routing, cutting, creasing and finishing a wide variety of substrates. With a generous cutting area of 3,500 × 2,100 mm and advanced features such as an automatic camera registration system, dual-motor X-axis drive and automatic tool-depth adjustment, it supports high-volume production of signage, display, packaging, automotive interior and furniture materials. This machine is built for speed, accuracy and flexibility — allowing print suppliers to deliver complex finishes, large-format boards and mixed substrate jobs with fewer manual interventions.

Key Specifications

Cutting area: 3,500 × 2,100 mm

Maximum cutting speed: up to approx. 1,500 mm/s

Cutting precision: ±0.1 mm

Maximum material thickness: up to approx. 50 mm

Supported formats: PLT, DXF, HPGL, PDF, EPS

Power requirement: 220 V/50 Hz or 380 V/50 Hz

Vacuum hold-down system (zone control) and dual X-axis motors for stable, high-throughput operation

Benefits

The Q-Cut 3521 allows print-finishing operations to be streamlined by integrating multiple functions (cutting, routing, creasing, punching) into a single platform. Its large working surface means oversized boards or multiple nested pieces can be processed in one pass, reducing setup time. The automatic camera registration and tool-depth control increase accuracy, especially useful for printed material that may have slight distortion or substrate variances. Because the machine can handle thick materials up to 50 mm and operates at high speed, it supports heavier duty tasks and large-format output without sacrificing precision. The vacuum hold-down system and dual-motor construction contribute to reliability and consistent results — key in a production-driven finishing department.

Designer / Production Tips

When designing for the Q-Cut 3521, it’s helpful to specify material dimensions and thickness ahead of time so the tool‐path, hold‐down zones and cutting head configurations are optimised. If your job involves dark or reflective substrates, ensure camera registration marks are clearly visible to avoid mis-alignment. For jobs that include routing or creasing on thicker boards, indicate the use of those tools so the correct tool modules are prepared. While the machine is fast, ultra-fine detail or extremely complex outlines may run more effectively if nested appropriately or broken into sub-jobs to maintain precision. For large nested layouts, consider bleed and margin allowances given the vacuum zones and table size; this will simplify finishing and reduce manual rework. Lastly, if you plan multi-material work (e.g., combining foam board, acrylic, corrugated plastic), provide a clear material list so the operator can select the correct blade, speed and vacuum suction configuration.