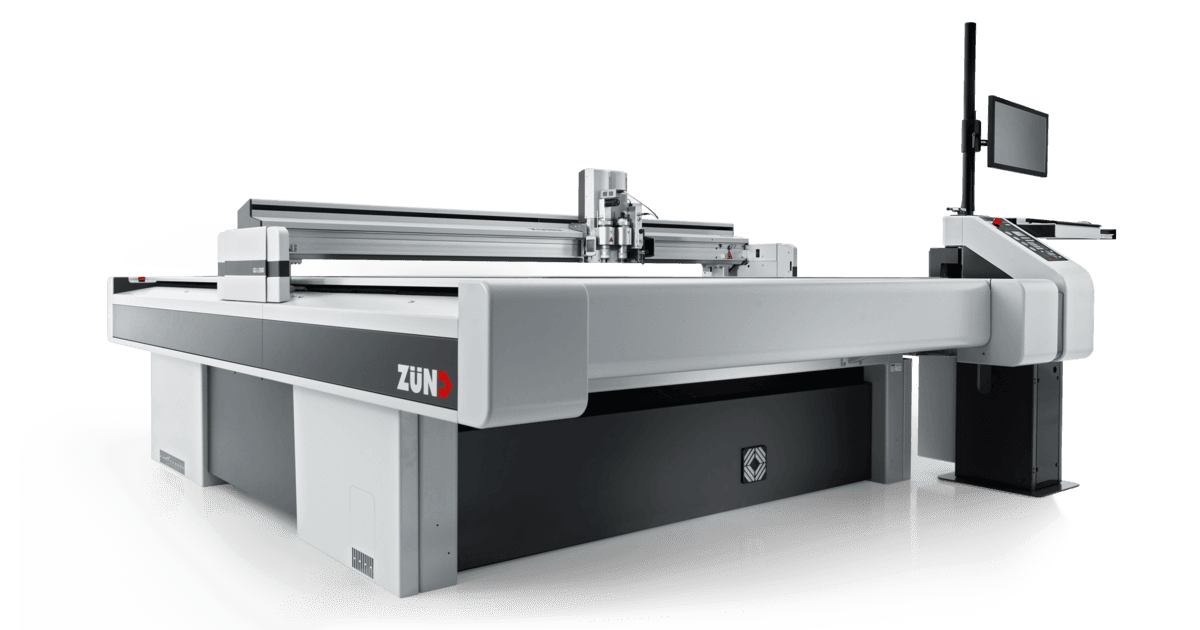

Zünd Cutting platform

The Zünd cutting platform is a precision digital finishing system engineered for versatility, speed and modular expansion. Built for print suppliers that require high-accuracy cutting, creasing, routing and finishing across rigid and flexible materials, it supports everything from display graphics and packaging to textiles and composites. With its Swiss-engineered drive systems, automated tooling, and open architecture, it fits modern production workflows and is designed for long-term investment.

Key Specifications

Working area options (examples): up to 3,200 mm × 3,210 mm.

Repeatability: ±0.03 mm.

Max material thickness (varies by model): up to approx. 110 mm for heavy-duty versions.

Tooling system: modular with knife, creasing, routing, oscillating, rotary blade modules.

Vacuum hold-down system with zoned control for optimal material fixation.

Automation ready: tandem operation, roll-off units, sheet feeders and robotic unload possibilities.

Benefits

This cutting platform enables a broad range of finishing operations on one machine—reducing the need for multiple dedicated devices. Its precision and repeatability mean high-quality output even on detailed jobs, improving consistency and lowering waste. The modular tooling system allows the device to adapt as production demands evolve—whether that’s routing composite materials, kiss-cutting intricate shapes or creasing corrugated board. Automation features and efficient material handling contribute to faster throughput and safer, less labour-intensive operation, making it a strong match for busy finishing departments.

Designer / Production Tips

When preparing files for this platform, clarify material thickness, substrate type and intended finish early—this ensures the correct tool (knife, router, creaser) is assigned and the machine depth and hold-down configurations are optimised. For high-volume or multi-material runs, nest jobs intelligently and separate them by substrate group to minimise tool changes and interruptive set-ups. For flexible media, enable the roll-off or sheet-feeder modules and provide clear edge-registration marks to maintain accuracy. And finally, for jobs involving oversized sheets or very thick substrates, check the exact machine configuration (beam height, transport system, load capacity) to ensure full compatibility and avoid bottlenecks.